The A4BLUE project has just entered its third year of project life and its solutions are taking shape. Partners are very satisfied with the work performed so far and therefore proud to illustrate the impressive progress that has been achieved.

Our solutions are not intended to replace blue collar workers but to make their everyday work life easier and enhance their work satisfaction via new adaptive workplaces that change and respond to their individual profiles and to the changing manufacturing environments. A4BLUE is currently working on the implementation of 4 demonstrators for the validation of the envisioned concept, which focuses on three aspects of these new workplaces: Sustainability, Adaptability, and Automation Mechanism for good interactions and collaboration between workers and robots.

The A4BLUE solutions are being tested and validated in four use case scenarios. They consist of two real industrial scenarios, at Airbus in France and CESA in Spain, and two laboratory-based scenarios, at IK4-TEKNIKER in Spain and RWTH Aachen University in Germany.

Airbus use case scenario

For the Airbus scenario, A4BLUE aims at improving the quality process of assembly, by actively involving several personnel categories, i.e. operators, quality supervisors, manufacturing engineers, and process planners. This is done by introducing a new intelligent system for bolt tightening in hydraulic assembly, involving a Smart Torque Wrench (jointly developed by Airbus and SamOutillage) and an Augmented Reality (AR) device (the Hololens glasses) which displays and guides operators through their work instructions . The AR device therefore shows information based on each operator’s individual profile and skillset to ensure an appropriate level of automation that optimizes the execution of the task using the torque wrench. The system measures and records at the same time real-time and synchronized information from operators, supervisors, engineers and process planners, providing a new and improved generation of assembly.

As a summary, the first results in the use case application include:

- Automation adaptation: the parameters of the smart tools involved in the assembly process automatically adapt themselves considering both the operation being performed and the related standard operating instructions.

- On the job training & guidance: Augmented Reality (AR) provides step by step personalised job guidance considering both the specific worker profile and the operation to be performed.

- Decision support: a dashboard makes information collected by the smart tools during assembly available to the Quality Inspector to support their decision making. This means that the Quality Inspector will no longer be required to manually check that the task has been effectively executed and at the same time facilitate error detection and correction.

CESA use case scenario

Within the CESA use case scenario, A4BLUE introduces the first collaborative automation in their assembly facilities which will reduce the high dependency on manual work within CESA and allow workers to use their time in a better and less exhausting way. The case includes:

- Safe Human-Robot collaboration: The deburring process is done by the operators with the support of the robot (the robot performs the most tedious phase while the operator performs the inspection and final smooth). Safety of the operator is ensured by a laser scanner detecting any movement around the robot and the defining safety zones (which are areas the operator cannot enter because it is too close to the robot).

- Automation adaptation: The deburring robot adapts its behavior to operator movements (i.e. it stops or slows down depending on workers proximity) and process variability (it executes the appropriate control program considering the ongoing work-order and it stops if there are chances of damaging the tool).

- Decision support: if some important events occur, intervention request are sent (i.e. collaboration and maintenance) depending on workers profile. Information provided on the dashboards is specific to the operator and supports maintenance workers decision making.

In addition, an Augmented Reality (AR) device is being implemented to provide the workers with comprehensive and simple information to guide them in executing their work. This will allow operators to share best practice techniques between one another which reduces training needs, since the operators will be guided through the assembly process by information adapted to their individual level of expertise.

IK4-TEKNIKER use case scenario

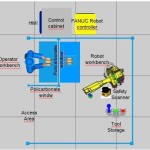

The use case scenario at IK4-TEKNIKER involves the assembly of a latch valve in a fenceless environment performed in close collaboration by researchers and robots, including activities such as final inspection and transport of the completed parts to the warehouse. The first use case application, the “alpha scenario”, involves the following key elements:

- Safe Human-Robot collaboration in a fenceless environment is supported by specific sensors (i.e. SafetyEYE and two safety laser scanners) allowing the definition of different safety zones and detection of any movement around the dual arm robot. These sensors perform a constant risk assessment ensuring safe interaction between the dual arm robot and involved workers.

- Context awareness takes into consideration the information provided by the dual arm robot (i.e. operation being performed and status) and the available manufacturing execution system (i.e. involved operator, work order, operation).

- Automation adaptation considers both the context and operators’ characterisation: i.e. the dual arm robot automatically executes the appropriate control program according to the reference of the part being assembled, and adapts the positioning of this part during the collaborative activity to the operators physical characteristics to avoid ergonomic risks.

- Multimodal and multichannel interaction enables the researchers to find the best way to communicate with the robots taking into consideration the context and their own capabilities and/or preferences. The basic actions are: START, RESUME and STOP and two interaction channels have already been included to support natural interaction: (1) natural speaking and (2) gestures considering both right- and left-handed operators.

- Decision support provides operators with the ability to intervene in the robots activity through emails and/or push notification (operators can ask for collaboration, inspection and maintenance) and a decision support dashboard is available with a user friendly interface and layout in line with the worker profile.

This work is continuing and is now focusing on the improvement of the features that are already in place and the introduction of new capabilities to implement the second use case application. New features are: an active safety mechanism for adapting the dual arm behaviour based on worker’s intention, the integration of a mobile robot for internal logistics, and the introduction of augmented reality to guide and support the assembly operators during the final inspection considering their individual expertise level. Do you want to see how it functions? Watch our video of this solution at: https://vimeo.com/271428696!

RWTH use case scenario

Within the RWTH use case the A4BLUE solution is being applied to enhance the assembly of electric vehicle prototypes. The assembly of the rear light as well as the break module is performed at electric vehicle ACM2 eTaxi. Recently, experiments have been conducted in order to measure the operator’s process performance without any technological support. Meanwhile the technological progress and implementation is ongoing. During complex operations like the assembly of the safety critical brake pedal and the rear light, the worker will be helped by augmented reality which will display instructions that will enable unexperienced workers to successfully perform the process without receiving direct guidance from a supervisor. This will improve the quality of work, reduce the training time needed for new employees, and achieve a high level of usability as this is essential for worker acceptance of the AR-solution. The worker will also be supported by an autonomous tool trolley which already reacts to human gestures and follows the worker on command in a test environment. Don’t believe us? Watch this video! As a next step, the tool trolley will be connected into the A4BLUE Cloud Framework and therefore the operator will be able to move it to specific assembly stations using voice commands. The automated tool will not only decrease the physical demands of the workers but also increase their productivity. Watch the RWTH case dedicated video here to see how this A4BLUE solution enhances the manual process and will improve workplaces!

Conceptualization and architecture of the A4BLUE Platform

The definition the A4BLUE Platform architecture aims at providing a solid playground to build the A4BLUE Adaptive Framework, considering the most recent trends with regards to the Reference Architectures (RA) for ICT platforms for manufacturing. To this end, the main outcomes of such initiatives were analyzed in order to depict the desired alignment between A4BLUE and these architectures.

Among the most interesting architectural approaches in the field of Industrie 4.0, the FIWARE for INDUSTRY (F4I) RA fits well with A4BLUE modular architecture since it is based on the integration of the real and the digital worlds through the mediation of the Internet of Things.

At the end of the 2nd year of project activities, one of the most important outcomes has been delivered in order to support all the foreseen implementation activities: we turned the Reference Model of the A4BLUE architecture into a set of concrete Functional Building Blocks (FBB) that support each functionality of the A4BLUE Framework. In A4BLUE, modularity, scalability and adaptability are also well supported. The next step is the continuous refinement of the A4BLUE FBBs, taking into consideration the feedbacks collected during the development and validation of the four use cases, with the aim of full integration of all the technologies we are working on.

Methodology for socio-economically sustainable design of optimal automation levels

At the end of the second year of project activities, we have almost completed the development of the methodology for the optimal automation level based on cost related aspects and worker satisfaction. With regard to the overall target of A4BLUE, it is crucial to connect economic and technical factors with usability and worker satisfaction to ensure the optimum adaptive and sustainable workplaces of the future. Currently the implementation of a software tool within the A4BLUE Cloud Framework has already started: it will enable operators to access the tool from any place and to analyze real-time data for re-evaluation of automation levels and activities to be performed.

Dissemination & Communication activities and the ACE-Factories Cluster

From the start of the project two years ago, all partners have been continuously engaged in dissemination and communication activities in order to increase the visibility of A4BLUE towards potential customers or partners. With this aim, during the second year, partners joined several international events, workshops, scientific conferences and exhibitions, always collecting positive and concrete feedback from stakeholders. In September and November, A4BLUE participated in two events.

Engineering illustrated the conceptualization and the architecture of the A4BLUE platform during the 9th international Conference on Intelligent Systems 2018 in Madeira Island, Portugal (25th -27th September 2018). The forum was the occasion to showcase our project in front of stakeholders and experts in intelligent control, artificial intelligence, decision support systems, soft computing, data mining and knowledge discovery, machine learning, intelligent measurement, etc.

A4BLUE joined the 2018 Aerospace Systems and Technology Conference which took place in London, UK, (6th-8th November 2018) where our Augmented Reality approach was successfully showcased. On the 8th, Airbus presented our application case using the Augmented Reality implemented by ILLOGIC during the Digital Design and Manufacturing (“Industry 4.0”) session.

Stay tuned further developments!